Positive Pressure Conveying Machine

The Dense-phase pneumatic conveying machine, which is also known as positive pressure conveying equipment uses compressed air (or inert gas) to convey materials, the pipeline pressure is higher than the ambient pressure. The materials in the sending bin are mixed with compressed air, under the...

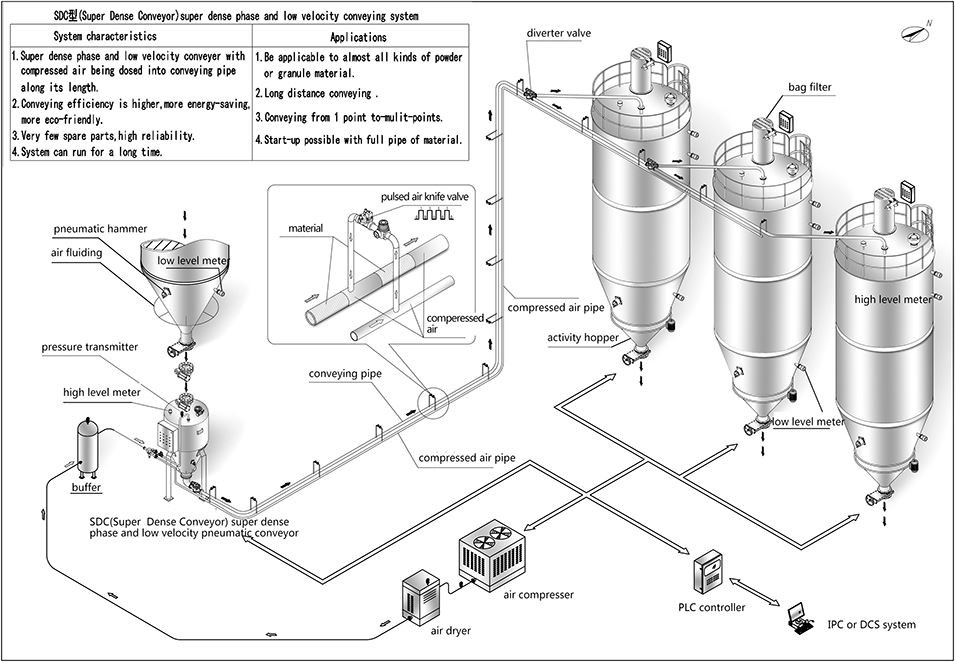

The Dense-phase pneumatic conveying machine, which is also known as positive pressure conveying equipment uses compressed air (or inert gas) to convey materials, the pipeline pressure is higher than the ambient pressure. The materials in the sending bin are mixed with compressed air, under the action of the compressed air, the materials are sent to the designated location through the conveying pipeline.

Features.

в—Џ The powder-gas mixing ratio is large, the mixing ratio of positive pressure dense phase conveying is 1:60, and the mixing ratio of positive pressure dilute phase conveying is 1-10.

в—Џ Low conveying speed, little damage to material particles.

в—Џ Conveying capacity up to 20T/h.

в—Џ The energy consumption is small, the gas contained in the powder is small, it is easy to realize the separation of powder and gas, the configuration of the transportation pipeline is flexible, and the production process is more reasonable.

в—Џ Few moving parts, closed conveying system, no dust.

в—Џ Can realize one-to-one or one-to-multipoint delivery.

в—Џ Integral 304 material or 316L material production, no dead corner, can be washed.

в—Џ The control system can be automated, but has high requirements for various electrical components;

в—Џ The working pressure is high, so long-distance transportation can be realized; the use of booster can realize ultra-long-distance transportation.

Flow Rate

How does a pneumatic conveying system work?

Pneumatic conveying systems work by letting air flow through pipes, imparting a propelling force that moves bulk products from one end of the system to the other. Pneumatic conveying requires a pressure difference between the beginning and end of the system, which is achieved by using compressors, fans or blowers.

What types of Pneumatic conveyor?

There are two main types of pneumatic conveying systems available: dilute phase and dense phase. Each is used for a different application and includes different functions.

Lean phase

The most commonly used pneumatic conveying systems are lean phase systems for granules and powders. Two sub-categories extend from the lean phase system:

Dilute phase

Dilute phase delivery systems use gas velocities greater than 17-18 m/s, lower vacuum or delivery pressures below 0.1 bar. In a dilute phase conveying system, the material particles are completely suspended in the air or gas stream, and the solids loading ratio is significantly lower.

This type of system is ideal for conveying low bulk density non-abrasive materials. Most systems will use side channel blowers or fans to move product along the duct.

Middle phase

In mid-phase pneumatic conveying systems, gas or air velocities typically exceed 17-18 m/s and vacuum or pressure up to 0.35 bar.

Particles passing through the pipe remain in suspension with relatively low concentrations or solid loadings. Extractors and Roots blowers are commonly used to push air or other gases through the system.

Dense Phase

Dense phase conveying systems are ideal if sensitive or fragile products are to be moved.

You can use these systems to process and transfer products at lower speeds, which helps prevent impact damage. Dense phase systems use a pulse of air to push the product through, followed by another pulse of air and product.

Unlike lean phase systems, dense phase systems require more precise calculations to design and proper timing. When using these systems, the overall density, size and stroke or length of the particles will help determine the air to product ratio.

Depending on the specifications of your application and the type of product you need to handle and transfer, you can find the right pneumatic conveying system to get the job done.

On-site photos

Dense-phase pneumatic conveying @2tph, Chicken powder conveying

Dense-phase pneumatic conveying @Maltose, 10tph

Positive pressure conveying equipment @Sodium Suffocate Powder, 10tph

Refrence list for Dense phase pneumatic conveyor

| Country | Customer name | Description | Product Handle |

Shanghai, China | Shanghai Baosteel | NPPC-150,4t/h | Quick lime powder |

Shanghai, China | Yihai kerry | NPPC-150, 12t/h | Granulated Sugar |

Jiangsu, China | Jiangsu Hongda New Material Co.,Ltd | 16t/h | silicon powder |

China | "A national corp." | NPPC-250,10t/h | limestone powder |

Shandong,China | LUXI Chemical | NPPC-150,7~10t/h | urea |

Rayong, Thailand | SCG chemical | NPPC-150,5T/h | PE |

Hot Tags: positive pressure conveying machine, manufacturers, suppliers, used, for sale,