Gyratory Sifter

1. Gyratory Sifter 1) Gyratory Sifter Introduction The gyratory sifter is an advanced industrial screener separator and high-performance gyratory industrial screening machine generating a gyratory vibration motion close to level plane at low angles in a reciprocating side to side motion. This...

1. Gyratory Sifter

1) Gyratory Sifter Introduction

The gyratory sifter is an advanced industrial screening equipment and high-performance Gyratory Sifting machine generating a gyratory vibration motion close to level plane at low angles in a reciprocating side to side motion. This unique industrial gyratory screen was designed to provide a cleaner cut of materials while still allowing higher screening capacity.

2) BENEFITS OF GYRATORY SIFTERS

● Easy access to the screens – operator friendly

● Even product distribution – much cleaner separation

в—Џ Higher sieving capacity

в—Џ Easy-to-tension screening media

в—Џ Low maintenance

в—Џ Reduced costs

в—Џ Improved productivity

3) Our Vibro Screen Range Include:

Brewery Pomace Gyratory Sifter

Calcium Phosphate Gyratory Sifter

4) Gyratory Sifter Features

Our team engineered the Gyrasift with several distinctive features to deliver a solution that meets the needs of industries sifting dry materials, such as fertilizer and other bulk solids. These features include:

в—Џ Side-to-Side Motion: With its gyratory sifter motion, the GyraSift provides exceptional screening quality. By separating materials of varying shapes, which is typical of raw dry goods, your company can maximize its production and product quality. This could lead to gains in revenue by building your consumer base and their confidence in your items.

в—Џ High-Throughput Screening: With its large number of revolutions per minutes, our gyrasifter equipment delivers an unparalleled level of throughput screening for dry materials, such as pharmaceutical products. This feature provides your operators and facility with the ability to optimize the quality and distribution of your goods, which can help you expand your reach and revenue.

в—Џ Hook-Style Screens: Thanks to its convenient hook style screens, our GyraSiftв„ұ industrial equipment provides operators with a hassle-free method for modifying screens without imposing unnecessary downtime on your facility. This engineering feat also saves your company the cost and maintenance of maintaining multiple screen panels, which lets you maximize your uptime.

в—Џ Easy-Tension Size Support: With its innovative design, our gyrasifter equipment offers compatibility with multiple sizes of easy-tension screening media. That feature lets the GyraSiftв„ұ support a range of dry application processes, which helps your company adapt to changes with ease and boost your overall production without sacrificing quality.

5) Specification

Deck | Model | Sieve dimension width * Length mm | Positive displacement strok mm | Power kW | Rounds per min r/min | A (mm) | B (mm) | C (mm) | D (mm) | Weight kg |

1 | NAFS0515 | 500X1500 | 52 | 1.5 | 940 | 2235 | 700 | 730 | 810 | 350 |

1 | NAFS1021 | 1000X2100 | 64 | 2.2 | 960 | 3280 | 960 | 1156 | 1200 | 960 |

1 | NAFS1030 | 1000X3000 | 64 | 4 | 960 | 4485 | 1050 | 1156 | 1200 | 1100 |

1 | NAFS1530 | 1500X3000 | 64 | 5.5 | 960 | 4236 | 1360 | 1778 | 1892 | 2300 |

1 | NAFS1836 | 1800X3600 | 76 | 7.5 | 960 | 5305 | 1500 | 2180 | 2430 | 3600 |

1 | NAFS2050 | 2000x5000 | 92 | 11 | 960 | 6770 | 1980 | 2245 | 2230 | 5000 |

2 | NAFS0515 | 500X1500 | 52 | 1.5 | 940 | 2235 | 700 | 730 | 810 | 400 |

2 | NAFS1021 | 1000X2100 | 64 | 2.2 | 960 | 3280 | 960 | 1156 | 1200 | 1080 |

2 | NAFS1030 | 1000X3000 | 64 | 4 | 960 | 4485 | 1050 | 1156 | 1200 | 1230 |

2 | NAFS1530 | 1500X3000 | 64 | 5.5 | 960 | 4236 | 1360 | 1778 | 1892 | 2600 |

2 | NAFS1836 | 1800X3600 | 76 | 7.5 | 960 | 5305 | 1500 | 2180 | 2430 | 3900 |

2 | NAFS2050 | 2000x5000 | 92 | 11 | 960 | 6770 | 1980 | 2245 | 2230 | 5200 |

3 | NAFS0515 | 500X1500 | 52 | 1.5 | 940 | 2235 | 760 | 730 | 810 | 450 |

3 | NAFS1021 | 1000X2100 | 64 | 2.2 | 960 | 3280 | 1050 | 1156 | 1200 | 1250 |

3 | NAFS1030 | 1000X3000 | 64 | 4 | 960 | 4485 | 1080 | 1156 | 1200 | 1500 |

3 | NAFS1530 | 1500X3000 | 64 | 5.5 | 960 | 4236 | 1460 | 1778 | 1892 | 3200 |

3 | NAFS1836 | 1800X3600 | 76 | 7.5 | 960 | 5305 | 1560 | 2180 | 2430 | 4100 |

3 | NAFS2050 | 2000x5000 | 92 | 11 | 960 | 6770 | 2040 | 2245 | 2230 | 5500 |

2. SIEVE CLEANING WAY:

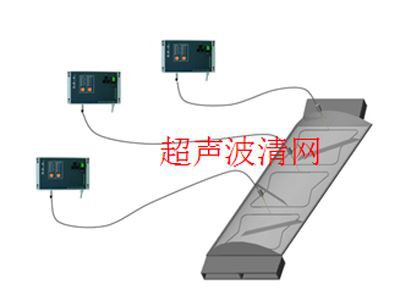

1) Ultrasonic cleaning way:

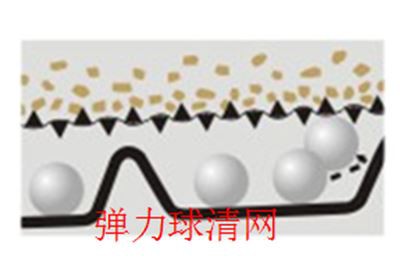

2) Bouncing ball cleaning way

3. Quick Sieve replacement

This is the most simple screen changing method in the large screening equipment at present, the new structure, open either end of the screen machine, you can pull out any layer of screen, replacement and inspection.

в–Ғ Single-layer or multi-layer, you can quickly and easily replace one layer of screen from both ends of the machine without affecting the others.Of course, if you wish to replace it from the top of the machine, you can easily remove the split-type dust cap without any lifting equipment.

в–Ғ The whole screen structure can be easily locked and loosened, avoiding the cumbersome operation of multiple clamps.The unique design allows you to easily inspect the inside without affecting the sieve and clean the ball tray.

The principle of mimicking the universal driving shaft of large cars is that the rocking force is softer and forms a basic rotating motion, increasing the flexibility of the equipment rocking.Also facilitate the effective removal of the swaying force.

4. On-site photos:

1) Mica screening project

2) Silica sand screening project

3) Garnet powder screening project

4) Indonesia Limestone project

Hot Tags: gyratory sifter, Gyratory screen, industrial screening equipment, linear vibrating screen, Gyratory Sifting machine, manufacturers, suppliers, used, for sale,