Pneumatic Suction type Dilute phase Vacuum Conveyor for powders and granules

A vacuum feeding machine is a kind of conveying equipment using vacuum suction to transmit particles and powder materials, the use of a vacuum feeding machine can greatly reduce dust pollution in the workshop, improve the degree of automation...

A vacuum feeding machine is a kind of conveying equipment using vacuum suction to transmit particles and powder materials, the use of a vacuum feeding machine can greatly reduce dust pollution in the workshop, improve the degree of automation.

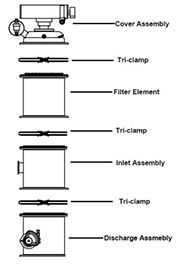

Structure of Vacuum Conveyor

| LZF series vacuum feeder is composed of the top cover assembly, filter assembly, feeding assembly, discharging assembly, and quick-opening clamp. |

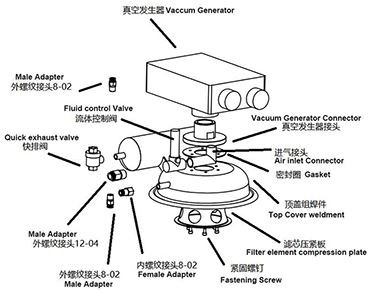

| The top cover assembly consists of a vacuum generator, a vacuum generator connector, a top cover assembly, and a filter element compression plate. Fastening screw, air inlet joint, internal thread joint 8-02, external thread joint 8-02, external thread joint 12-04, quick discharge valve, fluid control valve. The main function of the top cover assembly is to generate vacuum after compressed air enters the vacuum generator, and intermittently blowback to clean the filter element during operation. |

Main Functional parts of vacuum conveyor

1. Vaccum generator brand from Korea Economical and small-sized vacuum component | 2. Pressure gauge | 3. Reverse pulse air bag To clean the sticky powder on the surface of the filter | 4. Valve brand from England Durable and superior quality |

|

|

|

|

| 5. Filter material options в—Џ Stainless steel sintered felt material в—Џ Stainless steel sintered mesh material в—Џ Polypropylene sintered material в—Џ Teflon sintered material в—Џ Titanium sintered material в—Џ Glass fiber paper filter element в—Џ Polypropylene fabric filter materia в—Џ Needle felt filter material |  | ||

| 6. Bottom Flap valve Valve plate floating connection design, 360В° self-positioning function |  | ||

| 7. Rotary Valve Achieve continuous delivery, continuous blanking, and uniform speed blanking |  | ||

The basic working principle

LZF series vacuum feeder through the vacuum generator to provide vacuum power source, when the compressed air supply vacuum generator, vacuum generator will produce negative pressure to form vacuum airflow, the material is sucked into the suction gun, the formation of material airflow, through the suction tube to reach the hopper of the feeder. The filter separates the material from the air thoroughly. When the material is filled with the bin, the controller will automatically cut off the air source, the vacuum generator stops working, and the bin door automatically opens, and the material falls into the hopper of the equipment. At the same time, compressed air through the pulse back blowing valve automatically clean the filter, the above action repeated circulation, complete the feeding function. When the high material level sensor is set, it can automatically control the start and stop of vacuum feeding machine; Vacuum generator is a new, efficient, clean, economical and small vacuum component that uses a positive pressure air source to produce negative pressure, which makes it very easy and convenient to obtain negative pressure where there is compressed air, or where positive and negative pressure is needed in a pneumatic system.

Video:

Advantages of LZF series vacuum feeder:

в—Џ The conveying process is completely closed, no dust pollution, in line with food and drug production specifications;

в—Џ The high degree of automation can run independently, can also be integrated into the production line control, greatly reduce the enterprise labor cost;

в—Џ Compact structure, simple convenient dis-assembly, less energy consumption, low noise;

в—Џ Safe and reliable operation process, low cost of maintenance and accessories;

в—Џ Equipped with a reverse blowing tank and fast exhaust valve, reverse blowing instantaneous air volume, can quickly clean the filter element;

в—Џ Unloading using flap valve form can achieve the purpose of rapid unloading;

в—Џ Simple dis-assembly and assembly of the filter element, the open filter element is convenient to clean, no dead Angle;

в—Џ Vacuum generator using Korean DRMC brand, bottom valve rotary pneumatic pendulum cylinder using British Kinetrol brand, long service life;

в—Џ The connecting part adopts the S-Sline form, and the sealing parts are made of open mold, with good sealing performance.

Specification for Vacuum Conveyor

Model | Diameter | Vacuum Source model | Electricityconsumption | Air Consu ption | Capacity Starch @80mesh | Power source/control method | Note |

LSF210D-S10-50.50A-S4 | Φ210 | MVL200 | 0.2KW | 60Nmim³/H | ≤800KG/H | Vacuum Generator drive/Electronic control | Non-explosion proof |

LSF320D-S10-63.50A-S4 | Φ320 | MVL400 | 0.2KW | 100Nmim³/H | ≤1500KG/H | Vacuum Generator drive/Electronic control | Non-explosion proof |

LSS210D-S10-50.50A-S4 | Φ210 | RB52S-2 | 4+0.5KW | 4Nmim³/H | ≤800KG/H | Vortex Blower Drive/Electronic Control | Non-explosion proof |

LSS320D-S10-63.50A-S4 | Φ320 | RB72S-4 | 5.5+0.5KW | 8Nmim³/H | ≤1500KG/H | Vortex Blower Drive/Electronic Control | Non-explosion proof |

LSF210Q-S10-50.50A-S4 | Φ210 | MVL200 | / | 60Nmim³/H | ≤800KG/H | Vacuum Generator drive/Air control | Explosion-proof |

LSF320Q-S10-63.50A-S4 | Φ320 | MVL400 | / | 100Nmim³/H | ≤1500KG/H | Vacuum Generator drive/Air control | Explosion-proof |

LSF210D-S10-50.50A-S6 | Φ210 | MVL200 | 0.2KW | 60Nmim³/H | ≤800KG/H | Vacuum Generator drive/Electronic control | Non-explosion proof |

LSF320D-S10-63.50A-S6L | Φ320 | MVL400 | 0.2KW | 100Nmim³/H | ≤1500KG/H | Vacuum Generator drive/Electronic control | Non-explosion proof |

LSS210D-S10-50.50A-S6L | Φ210 | RB52S-2 | 4+0.5KW | 4Nmim³/H | ≤800KG/H | Vortex Blower Drive/ Electronic Control | Non-explosion proof |

LSS320D-S10-63.50A-S6L | Φ320 | RB72S-4 | 5.5+0.5KW | 8Nmim³/H | ≤1500KG/H | Vortex Blower Drive/Electronic Control | Non-explosion proof |

LSF210Q-S10-50.50A-S6L | Φ210 | MVL200 | / | 60Nmim³/H | ≤800KG/H | Vacuum Generator drive/Air control | Explosion-proof |

LSF320Q-S10-63.50A-S6L | Φ320 | MVL400 | / | 100Nmim³/H | ≤1500KG/H | Vacuum Generator drive/Air control | Explosion-proof |

LCS50L-S10-63.50G-S4 | Φ500 | RB72S-4 | 7+1KW | 12Nmim³/H | ≤3000KG/H | Vortex Blower Drive/Electronic Control | Non-explosion proof |

LCS50L-S10-63.50G-S4-EX | Φ500 | RB72S-4 | 7+1KW | 12Nmim³/H | ≤3000KG/H | Vortex Blower Drive/ Electronic Control | Non-explosion proof |

Note:

1, Air control type is intrinsically safe which is suitable for use in any explosion-proof occasions. (The Air control method cannot be realized under the condition of the vortex blower)

On-site Photos

1. Flour Vacuum Conveying and surge hopper | ||

| ||

2. Tea powder conveying, dosing, grinding and storage | ||

| ||

3. conveying particle metering system | ||

| ||

4. Vacuum conveyor with mill | 5. Matching with vibration screen | 6. Feeding+milling+screening |

|

|

|

7. Bag dump station, Vacuum Conveyor, Ultrasonic vibration screen | ||

| ||

Application:

в—Џ Can be widely used in a variety of industries:

в—Џ Grinding materials: silicon carbide, silicon powder, glass beads, corundum

в—Џ Chemical powder: pigment, powder coating, TMTD, Vc, lubricant, enamel powder

в—Џ Battery materials: graphite, toner, toner, lithium iron phosphate, etc

в—Џ Medicine: Chinese medicine powder and Western medicine powder

в—Џ Powder metallurgy: iron powder, copper powder, titanium powder, alloy powder

в—Џ Edible powder: sweetener, single glycerin, sugar, fragrance, starch, pigment

в—Џ Other powders: magnetic materials, cosmetic powders, etc.

Hot Tags: Pneumatic Suction type Dilute phase Vacuum Conveyor for powders and granules, piab vacuum conveyor, pneumatic vacuum conveyor, manufacturers, suppliers, used, for sale,